SmartBooster®

Stand-alone auxiliary

wire feeder

This intelligent electric "stand-alone" rear auxiliary feeder is equipped with touch-screen controls, password-protected digital settings, Ethernet & USB ports, 3-colour light tower and possibility to record productivity data.

It is available in two models:

SMB Plus and SMB HP.

The 24 Volt transformer works with worldwide currents.

SMB Plus

Part Number 1201.400

Equipped with a 100W motor for feeding wires through Maxiglide conduit runs up to 30 meters.

SMB HP

Part Number 1201.450

Equipped with a 400W motor for wire farms, larger gantries and Maxiglide conduit runs up to 100 meters).

SMB Advantages

1

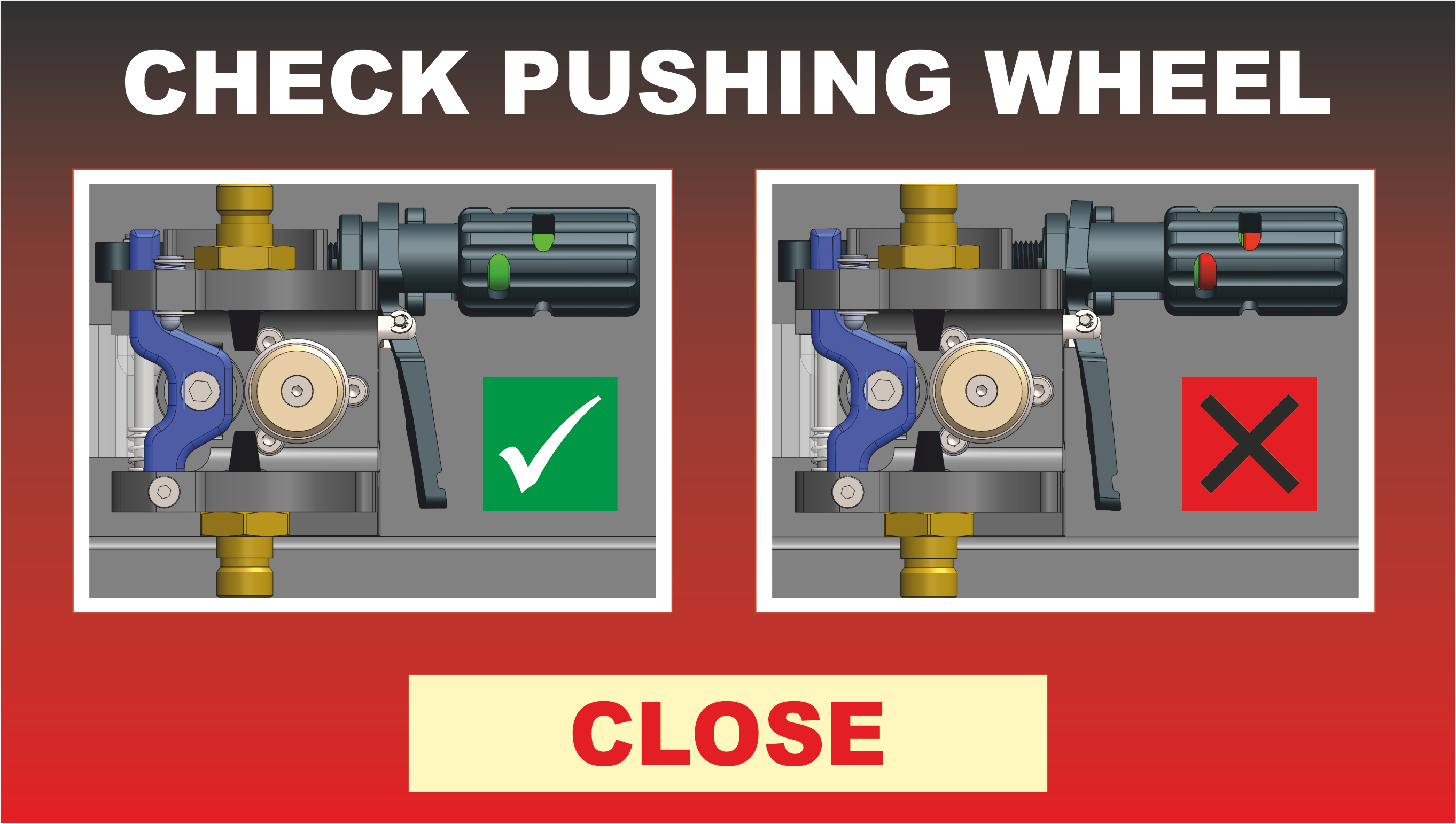

The equipment assists the front feeder by pushing the wire through the conduit with a minimum maintenance required (periodic replacement of the pushing wheel).

2

The universal 24v transformer works with all world voltages (ranging from 90 to 260V).

3

The USB port allows software updates and the saving of weld data.

Through the Ethernet port, SmartBooster can be directly connected to a remote device such as a wifi access router, network terminals or mobile phone and monitored using a VNC viewer.

4

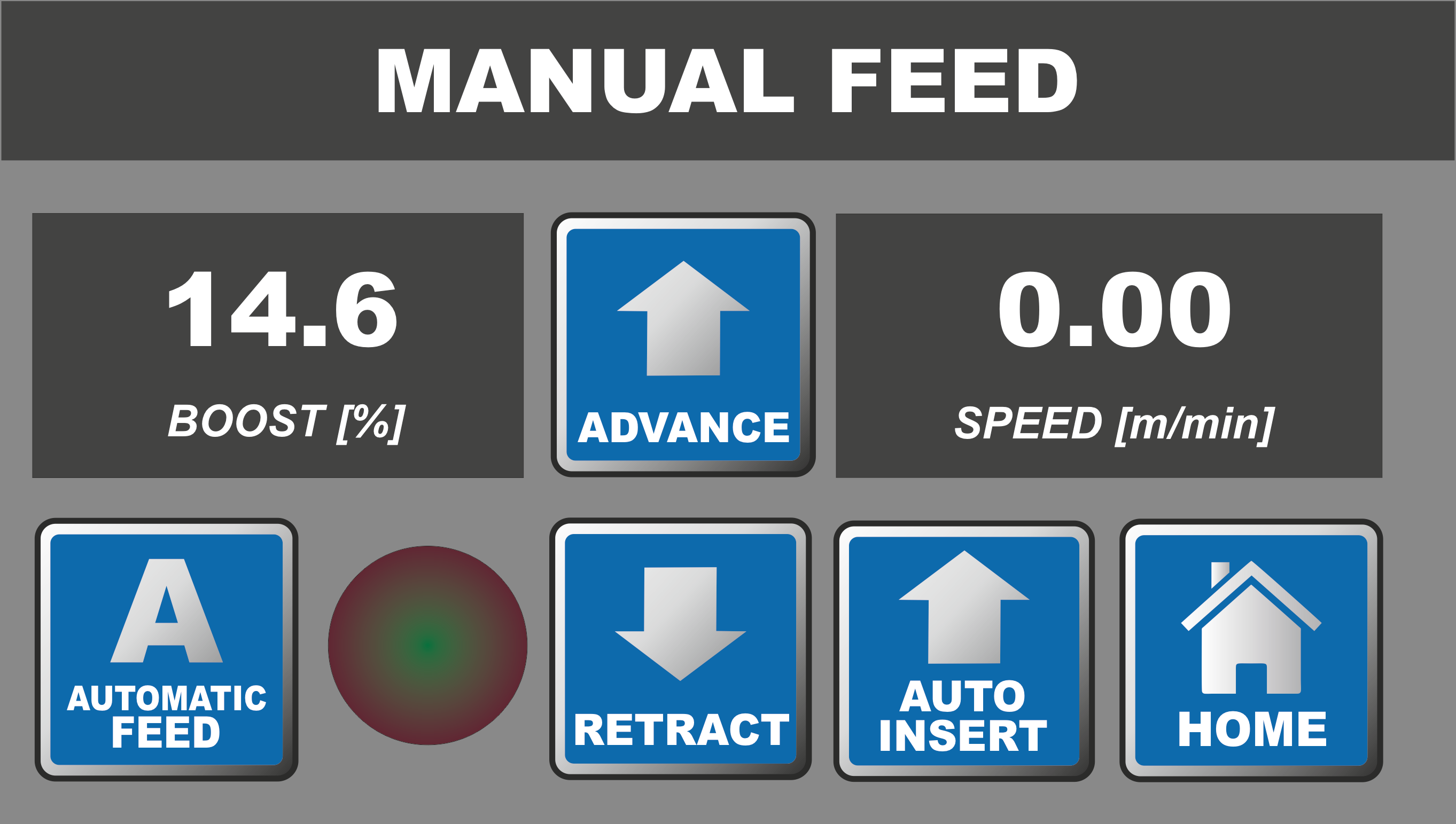

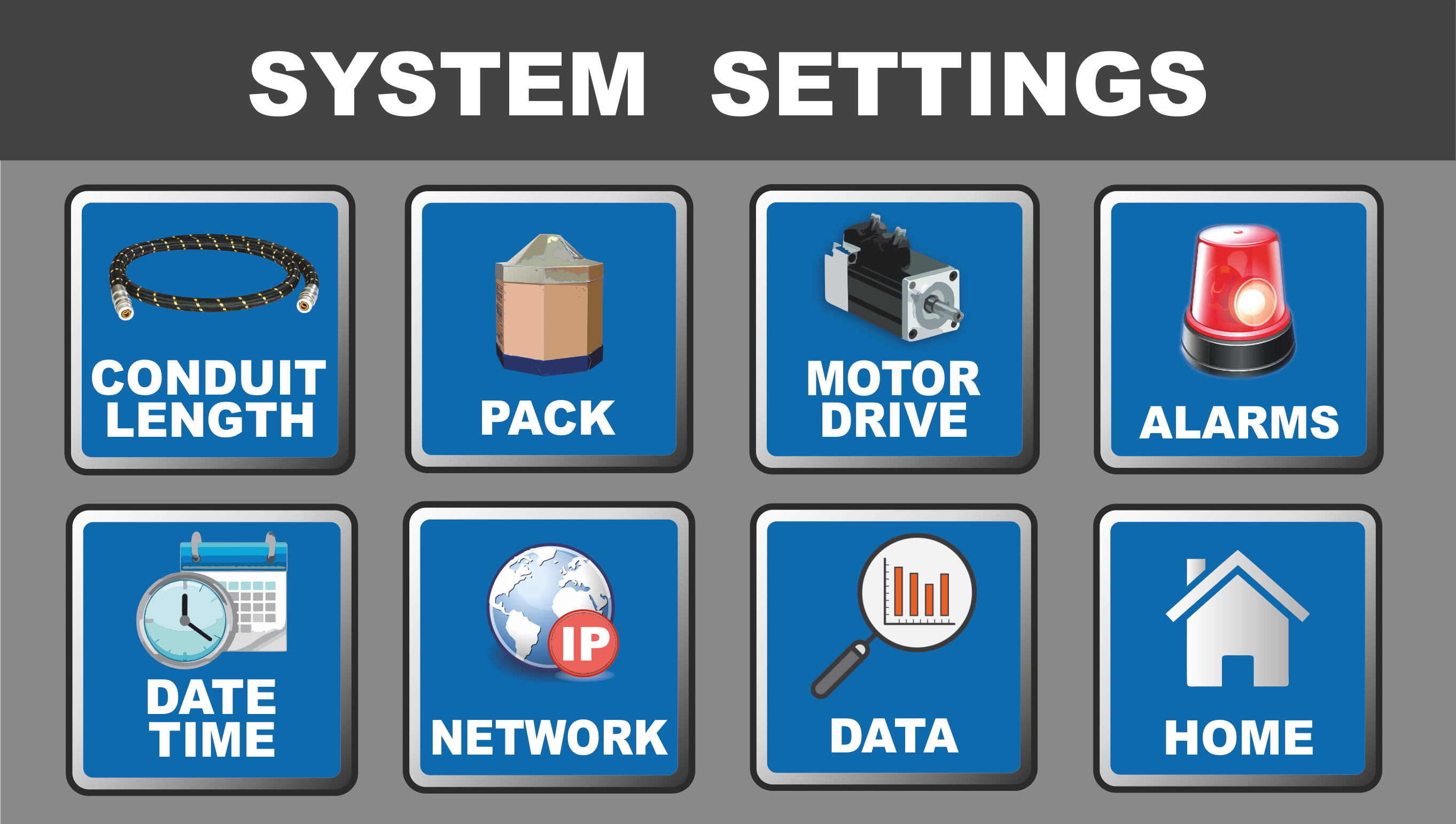

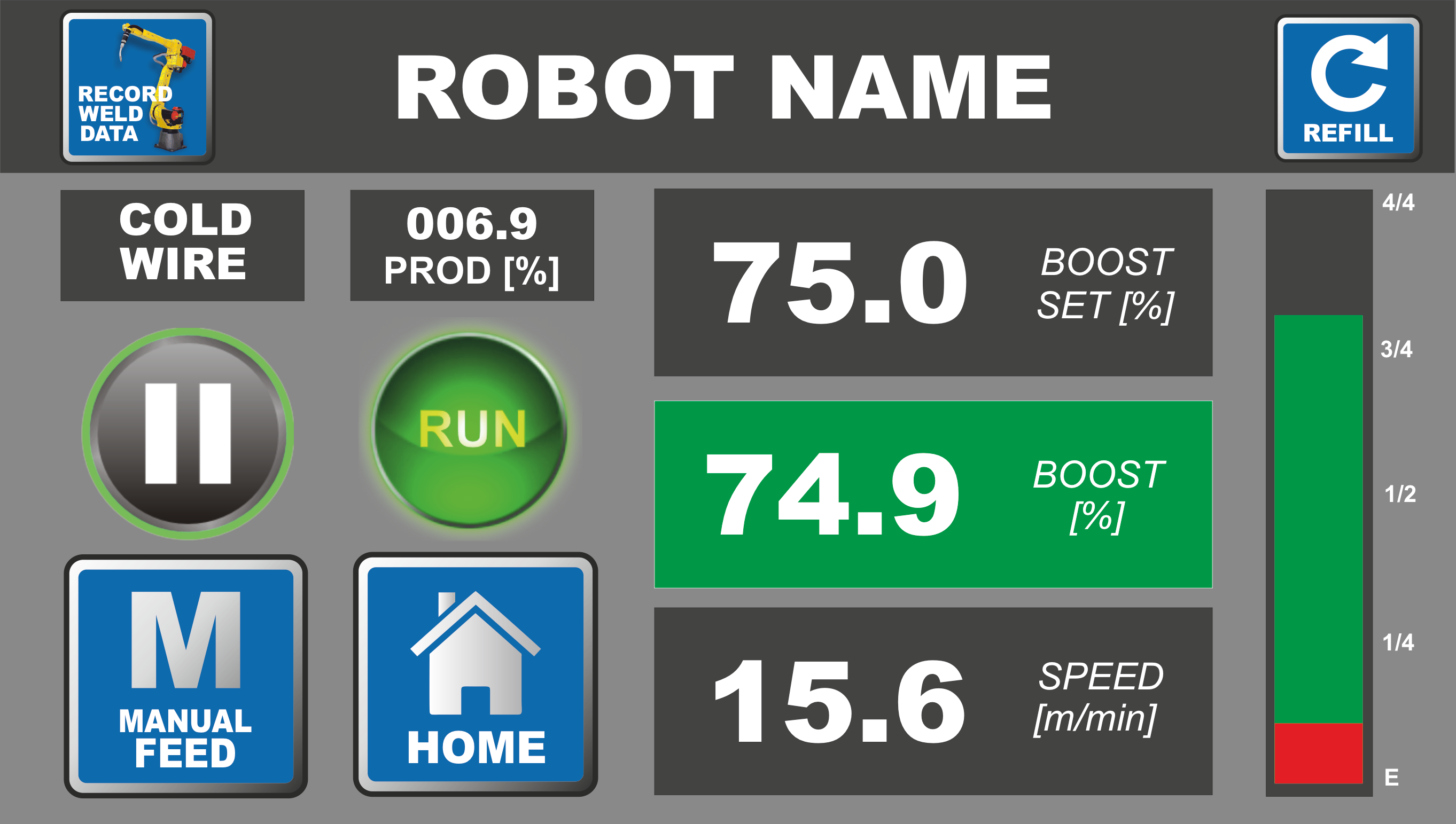

The touch screen controls permit an accurate digital adjustment of the device functions and settings and provide a visual monitoring of the device performance.

5

Assisted manual initial wire threading: after the the conduit length has been set in the "settings" menu, the auto insert function automatically inserts the set length plus one extra meter. Wire advancement can be monitored while the wire feeding is in progress.

6

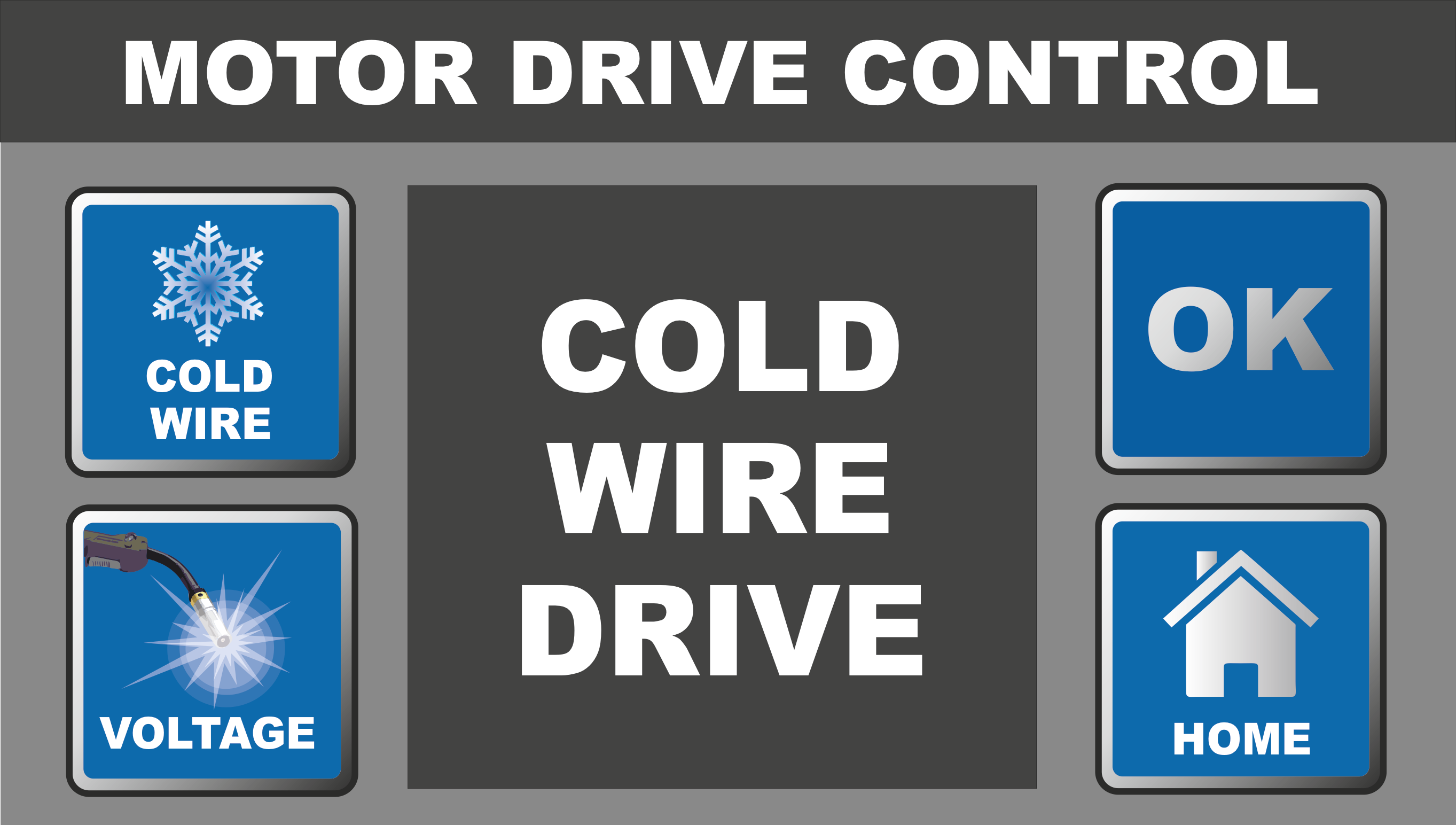

The driver controlled motor torque can either be activated by the contact with the wire (voltage mode) or with two different torque adjustments in the cold wire mode: stand-by boost (while performing maintenance operations) or working boost (when actively welding).

7

The parameter settings are password protected to prevent unwanted changes. Read the operating manual instructions for editing and saving the adjustments.

8

The lifetime free software updates are available on this website at the SUPPORT > SOFTWARE section. In case of malfunction after a software update, the former version is also available for download and restore.

9

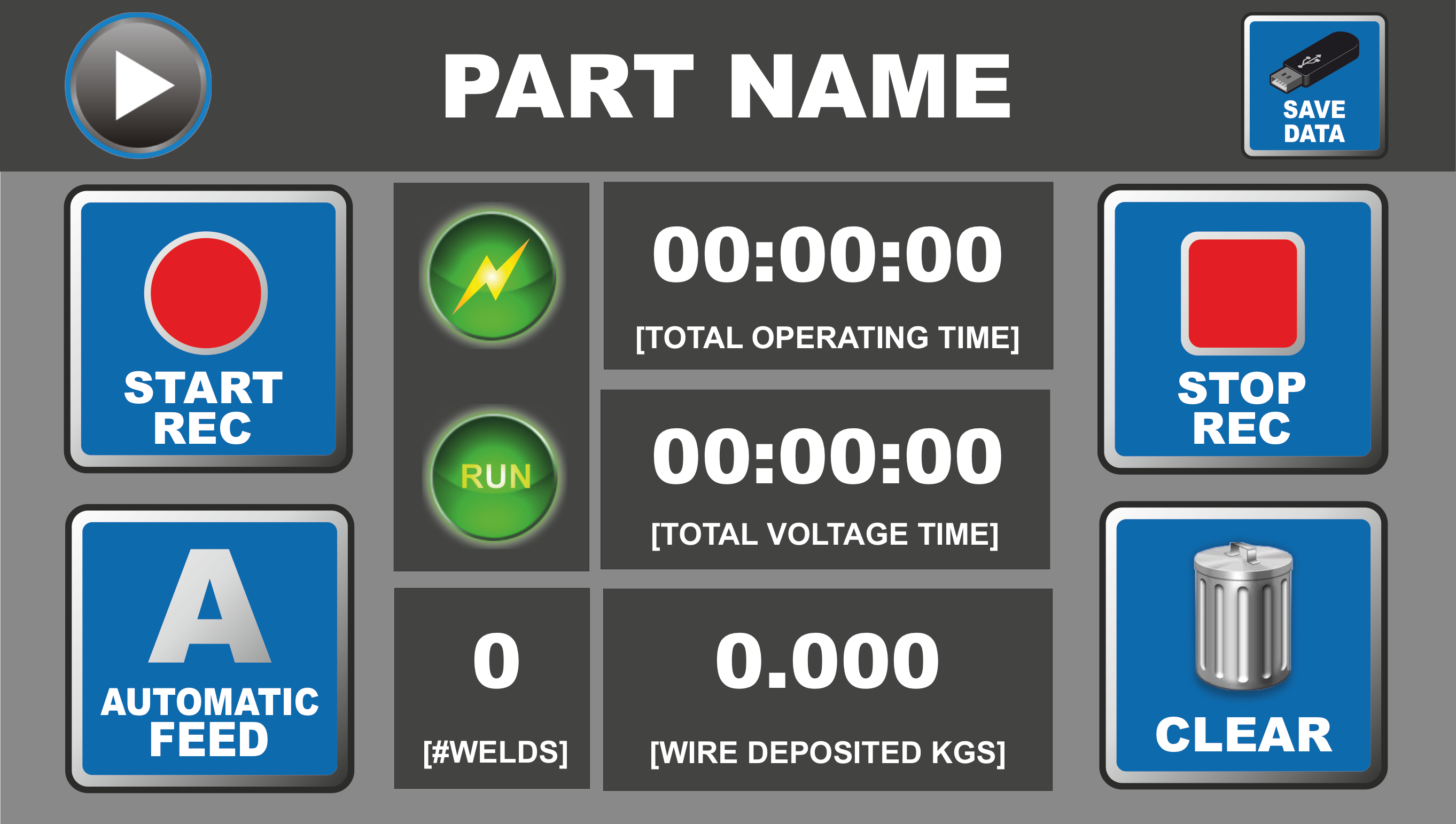

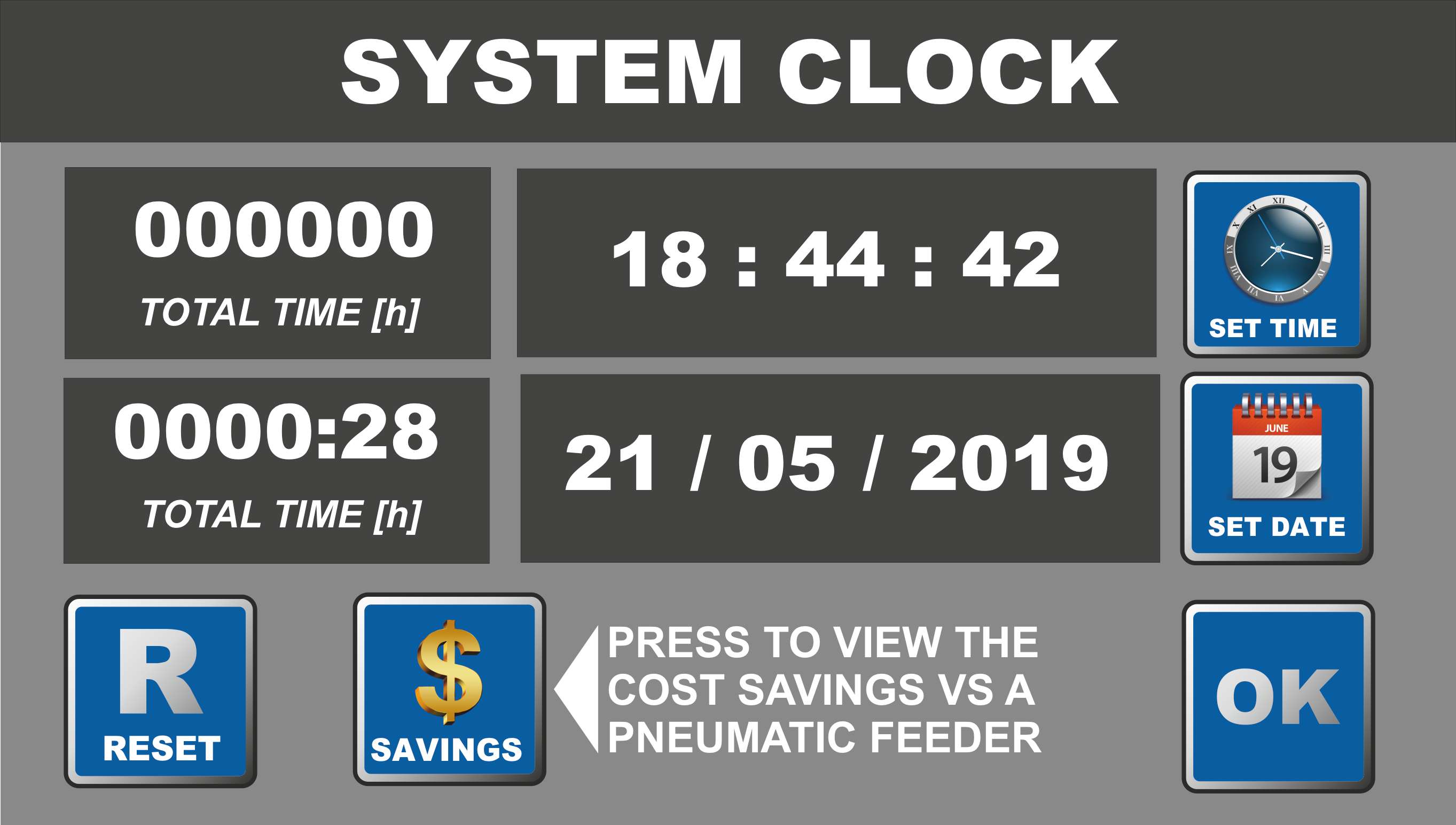

The device allows the accurate recording of cell welding & performance data and can measure the actual wire usage during the welding process.

10

The optional connection box gives the robot PLC the full control for remote wire advance & retract, low wire level alert signal and detection of wire end in the bulk pack.

11

The user-friendly colour codes on touch screen, light tower and device help verify the correct pushing of the wire or promptly identify possible wire feeding issues: "green" means that the system is functioning correctly while "red" indicates possible malfunctions or alarms. For more details refer to the instruction manuals.

12

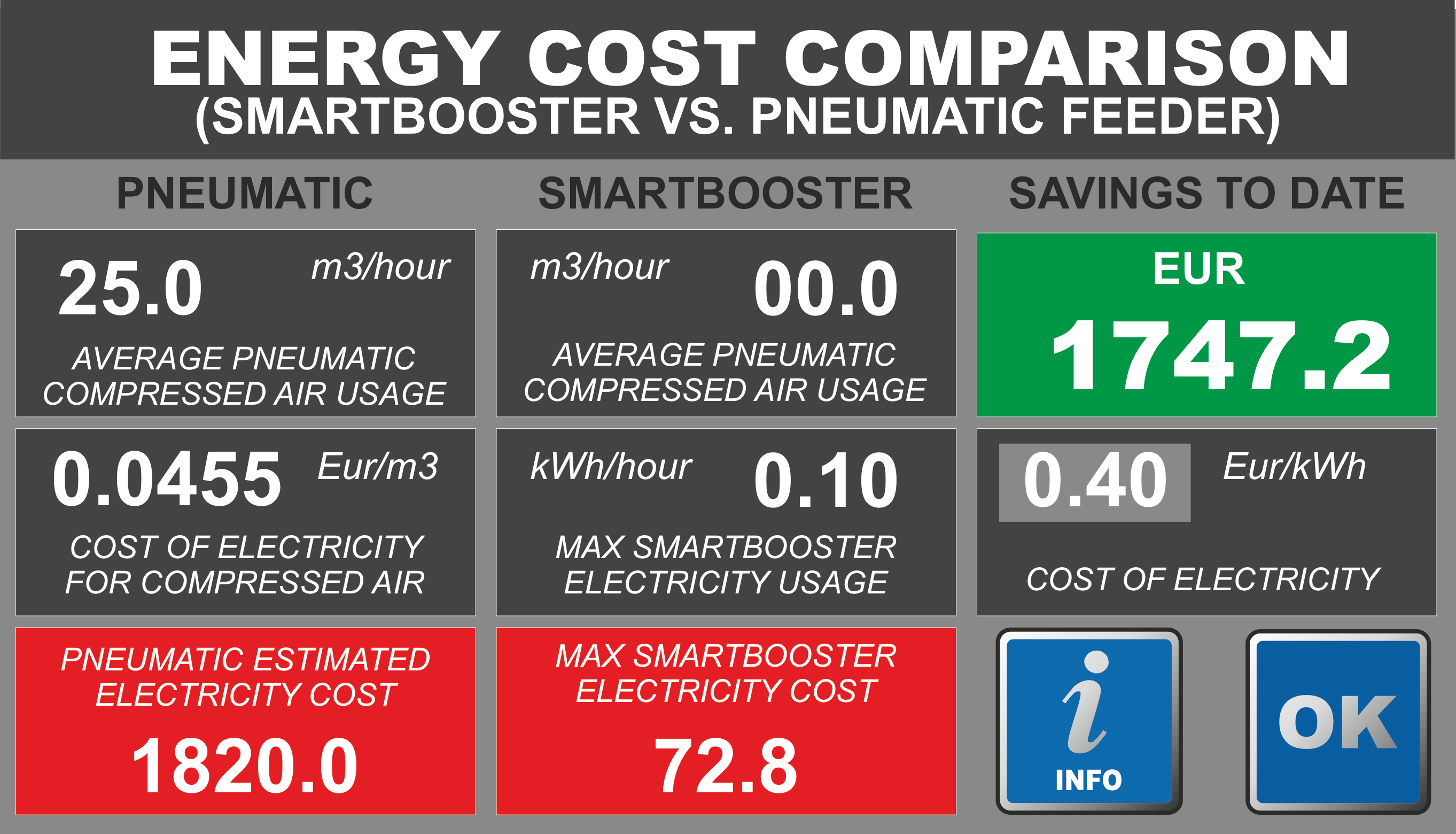

One of the most common "stand-alone" auxiliary rear feeders, the so called "pneumatic" feeder, is activated by compressed air, which has a reputation in the industry for been very expensive to produce. On the contrary SmartBooster is 100% electrically powered.

The "energy cost comparison" feature of the SmartBooster keeps track of the active wire feeding hours and provides an updated calculation of the energy savings.

Are you presently using a pneumatic rear auxiliary feeder or planning to buy one?

Populate the editable fields with the relevant information, such as your electricity cost per KWh, the working hours per day and working days per year, and then click the button below to calculate your savings using a SmartBooster instead of the pneumatic feeder.

For a correct layout,

we recommend viewing this page on your computer.

SmartBooster Accessories

Light Tower

The light tower, an extremely useful and common tool in many industrial applications, provides in real time visual alerts: it either confirms that everything is working fine and the wire feeding correctly or it signals the presence of possible negative events and anomalies: Green = OK, Yellow means "current detected on the wire" and Red stands for anomaly or alarm. On the contrary, with conventional stand-alone rear feeders it is often impossible to verify if everything is working fine.

(refer to the light tower instructions in the support section for more details)

Pushing Wheels

Part Number 1201.100-006SP

Part Number 1201.100-006SG

The pushing wheel is the only SmartBooster component that requires periodic replacement, as part of the maintenance program. The center plastic support does not necessarily need to be replaced, unless damaged.

Use 1201.100-006SP for 0.90-1.00mm

Use 1201.100-006SG for 1.20-1.40-1.60mm

Pushing Wheels

Part Number 1201.100-006OP

Part Number 1201.100-006OG

The outer metal cover has two identical "V" grooves. After one groove is worn out, the cover can be rotated in order to make the wire contact the new groove. The groove wearing out depends on the wire grade and hardness. The harder the wire, the faster the wearing.

Use 1201.100-006OP for 0.90-1.00mm

Use 1201.100-006OG for 1.20-1.40-1.60mm

Remote Control Box

Part Number 1201.400-900

SmartBooster is a stand-alone feeder but in many cases the robot PLC needs to take over full control of its peripheral devices and this accessory allows the robot to control the auxiliary rear feeder when performing commands such like wire advance and retract, besides prompting warning messages in case of malfunctions or alarms.

Empty Pack Sensor

Part Number 1201.755

This reliable mechanical sensor can conveniently warn that the bulk pack is empty and instantly stop both the main wire feeder and the SmartBooster from feeding. After the system has come to a halt, a residual length of wire from the empty pack remains available to be joined together with the wire start of the new pack (using a butt-welder). This procedure can help achieve a significant reduction of the pack changeover downtime.

Support swivel Arm

Part Number 1201.600-100G

It is always strongly recommended to work with the SmartBooster perfectly perpendicular on top of the welding wire pack. Sometimes however the forklift operator is in a hurry and drops the pack at a slightly offset position on the floor. Thanks to its construction, the arm angle can be quickly and easily adjusted in order to ensure that the SmartBooster pushing wheel is always perfectly aligned with the dome hole through which the wire exits the pack.

Floor Base

Part Number 1201.600-300

Vertical Stand

Part Number 1201.600-300

The SmartBooster installation kit includes a yellow base which can be anchored to the floor and a 2000mm aluminium 45x45 profile stand to carry the SMB holder arm. The two items are sold separately, since the stand can also be attached to a wall. Prior to drilling holes for the floor base, verify that there are no heating or other pipelines passing underneath.

Conduit with SMB Quick Connector

Part Number 1201.750

This (variable) length of bare conduit equipped with a quick connector at one end, guides the wire from the SmartBooster to the pack dome exit hole. It safely prevents any direct contact of the wire during the welding electric arc and, at the same time, it protects the wire itself from all risks of contamination.

Wire Curver

Part Number 6001

When converting from conventional small spools to larger drums, the wire stick-out can sometimes assume an erratic behaviour and generate "wavy" weld beads, specially in those applications where the equipment features very straight welding guns which have been originally designed to work only with spools. This tool can impart the desired plastic deformation and a curvature on the wire, similar to the one the wire has when coming off a spool. It must be said that a proper adjustment requires skills and could turn into a time consuming job. It is therefore preferable to replace a straight welding gun with a curved one.